What is a Wire Mesh Filter?

A wire mesh filter is a device made of interwoven wire strands that is used to separate, sieve, or filter a variety of materials. The wire mesh can be made from various materials, such as stainless steel, brass, or other metals, and the size of the mesh can be tailored to suit the specific filtering application.

Wire mesh filters are commonly used in a variety of industries and applications, including air and fluid filtration, chemical processing, food and beverage processing, and oil and gas production. They are often used to remove contaminants or impurities from liquids or gases, or to separate larger particles from smaller ones.

Wire mesh filters are known for their durability and reliability, and they can be used in a wide range of operating conditions. They are also easy to clean and maintain, and can be used repeatedly without requiring replacement.

We work in conjunction with the customer to meet their needs. Whether the customer needs a simple standard mesh filter or a complex custom mesh filter, we help design and manufacture their optimal filter.

We’re here to make your custom wire mesh filter.

The Roles of Wire Mesh Filters

Wire Mesh Filters For Fluid Rectification

Liquids flowing through pipes are often turbulent. A wire mesh filter can rectify this turbulent flow and ensure that the flow of the fluid steadily and efficiently reaches its destination. Wire mesh filters may also silence noise associated with this flow.

Wire Mesh Filter Clogging Counter Measures

Often times unwanted particles and objects can flow through pipes and without any sort of wire mesh filter this can lead to the pipe becoming clogged. To combat this, a wire mesh filter is press-fitted in the direction opposite of the flow. Our wire mesh filters are designed with large filtration areas and reinforced wire mesh to ensure that the filter does not get damaged under the pressure of being against the flow.

Collection of Foreign Substances

Wire mesh filters can be fitted in the direction of flow inside the pipe. This leads to foreign substances being both stopped and collected by the filter, protecting the pipe’s destination from being exposed to unwanted materials.

Wire Mesh Filters for Gas and Liquid Separation

The gas and liquid in refrigerants can be separated during the mist state using a special filter, such as an accumulator filter. Droplets of water collect on the wire mesh, eventually falling down. Only the gas is able to pass through the filter. The liquid refrigerant, which has been accumulating at the bottom, eventually evaporates and becomes gas, starting the next cycle of separation.

The Main Roles of Wire Mesh Filters

| 1. Foreign Material Removal | Collects foreign matter such as dust, sand, dirt, and other various scraps flowing through the pipes. |

| Increases machine performance, improves efficiency, and extends the machine’s lifespan. | |

| 2. Flow Turbulence Correction | Rectifies turbulent flow of liquid within the pipe |

| Controls the flow rate, mitigates sudden changes in pressure, and reduces noise. | |

| 3. Gas Liquid Separation | As the name implies it separates gas from liquid. |

| Liquid particles are removed, and only gas is able to pass through the filter. |

Creation and Features of Wire Mesh Filters

Mesh Weaving Process

Mesh is woven employing the same methods as traditional textiles. Metal wires are woven together to create a metallic mesh screen. For metal mesh molding (especially the blank and draw process) this is suitable for mass production. Woven mesh also has a cheaper unit price than etched mesh, leading to a cheaper overall filter.

In addition, the strength and size of the mesh can be adjusted according to how the mesh is folded. Therefore woven mesh can accommodate a wide arrange of needs. Iron wires are welded together to create sintered mesh, which prevents frayed wires and misalignment from occurring. Multiple mesh screens are stacked to achieve high filtration performance and excellent pressure resistance levels.

Etching Process

Etching is a method of making holes in a thin metal plate, such as stainless steel, by corroding it with an etching solution (i.e ferric chloride). The original plate cost is low, and it is fine for a small order quantity. However, the manufacturing unit price is higher than that of woven mesh processing, make it less optimal for a large order. Since the filter has been etched instead of woven, it does not have issues with fraying, burrs, or misalignment.

Perforated Metal

Perforated metal is created via metal punching. Metal punching is the process of punching holes out of a plate shaped object. A relatively large hole can be punched out, with a hole diameter of 0.5 mm or more and a pitch of 1.0 mm or more. Since a general-purpose mold is used, it can be manufactured for a relatively low cost. However, this method is not ideal for manufacturing filters with small wire diameters.

Applications of Wire Mesh Filters

Our mesh filters are used in over 60% of Japanese air conditioners. In addition to this, our filters are used in automobile engines, car air conditioners, refrigerators, washing machines, gas stoves, gas burners, water heaters, EcoCute systems, vending machines, elevators, water faucets, purification devices, and countless other machines.

The demand for mesh filters for use in next-generation vehicles such as fuel cell vehicles and electric vehicles, hydrogen station dispensers, and aerospace is expanding infinitely.

Vantech is making use of its abundance of experience and technical know-how to break into emerging industries. Vantech will contribute to the development of next generation products to keep up with the changing times.

Wire Mesh Filter Selection Guide

Shapes and Types of Wire Mesh Filters

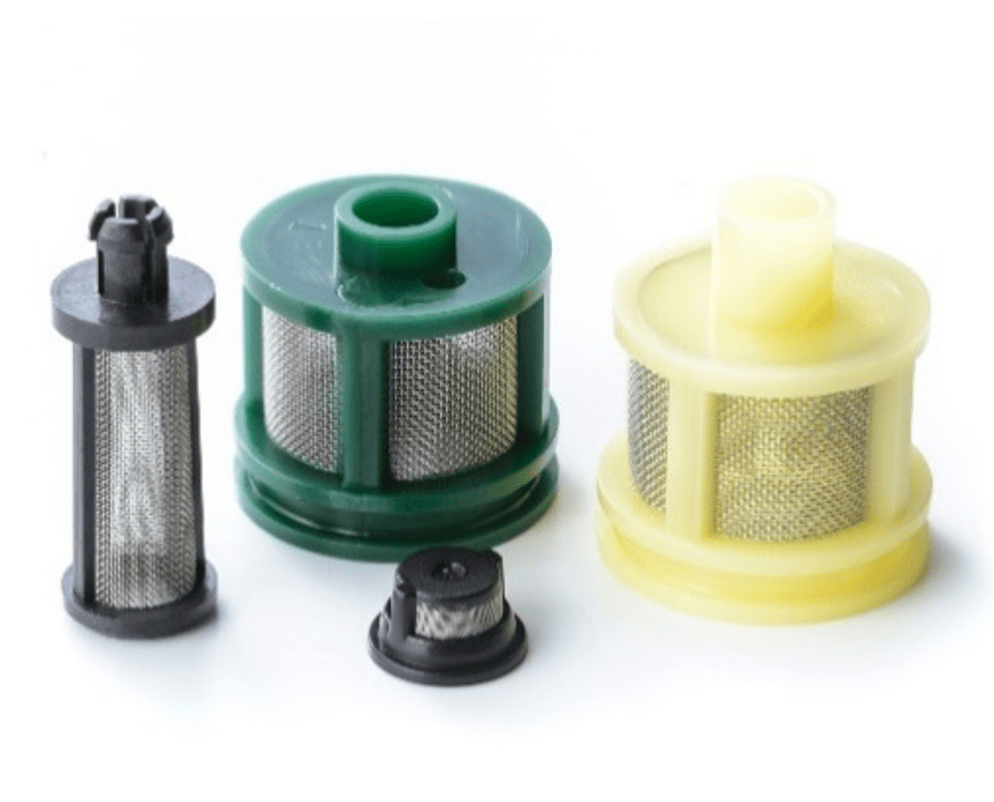

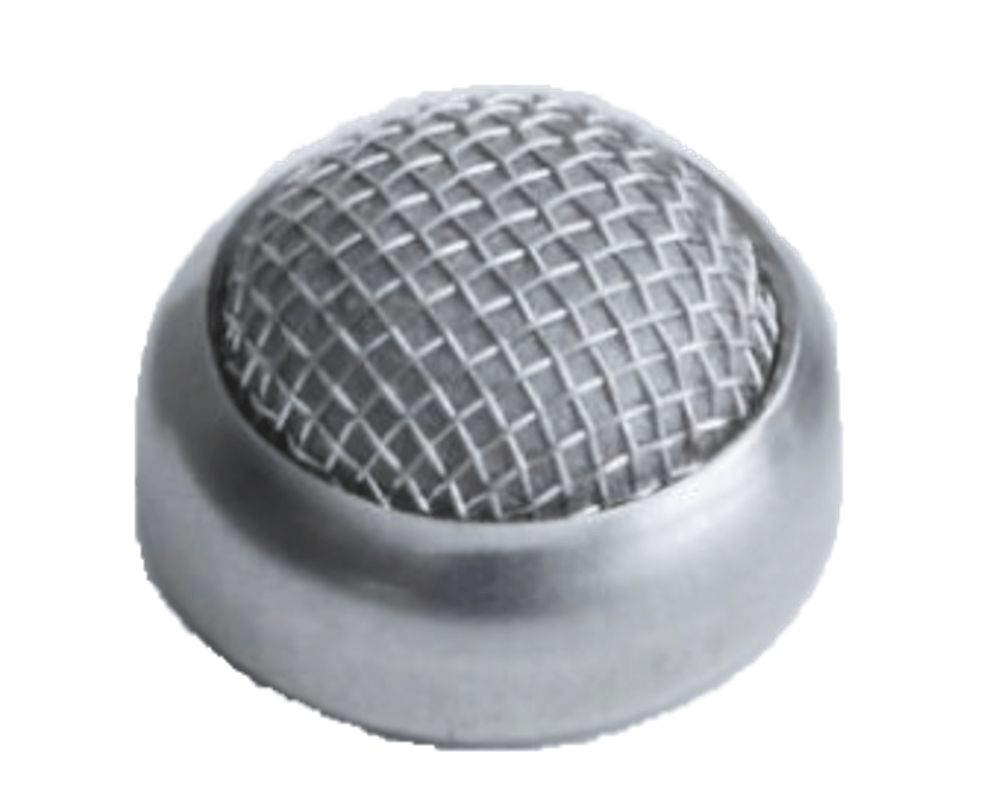

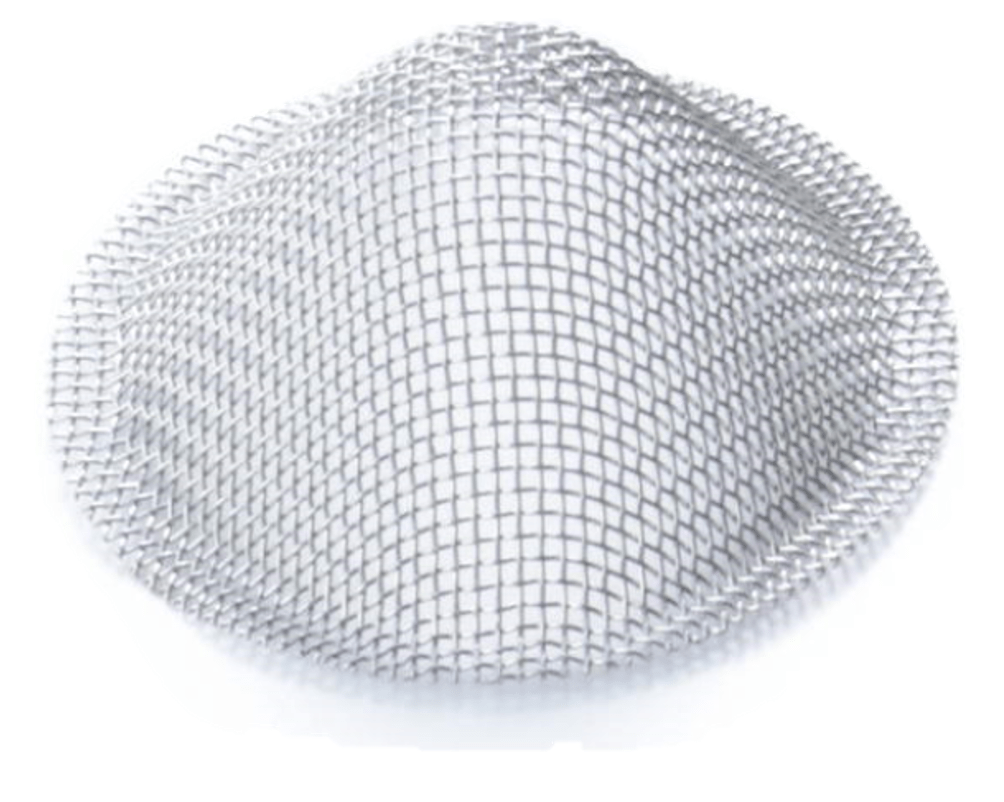

Micro Basket Mesh Filters

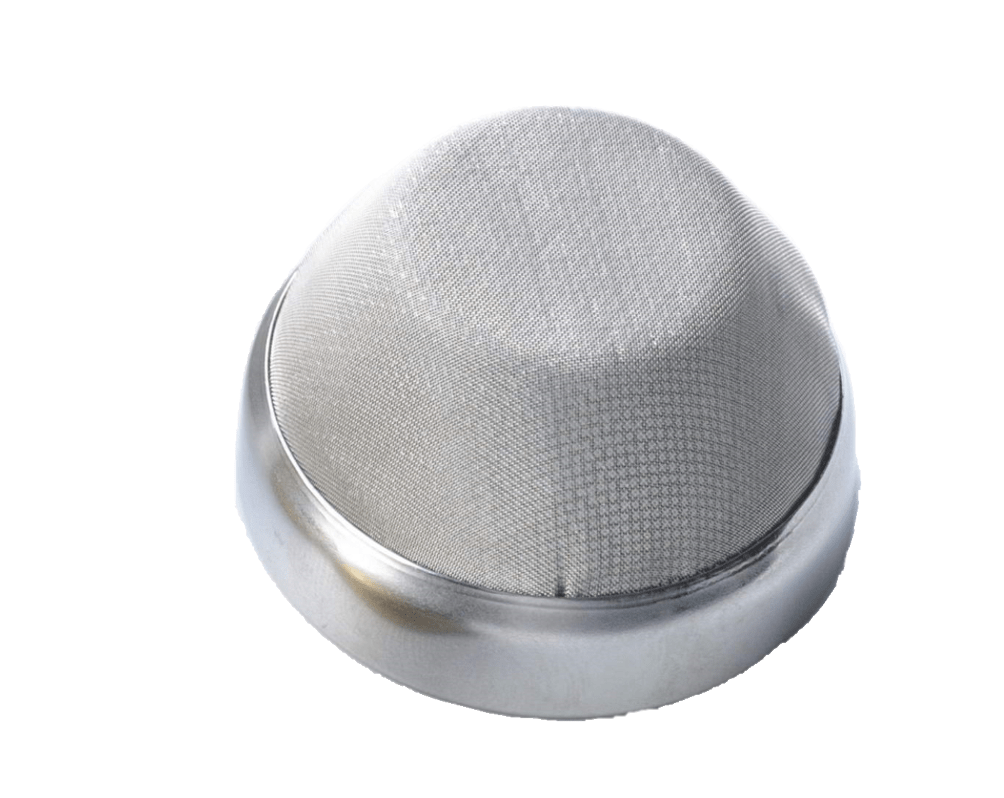

Micro Basket Mesh Filters

The mesh micro basket filter, or mesh cap filter, is Vantech Co., Ltd.’s most commonly produced type of filter. Most of these filters are relatively small in size, with an outer diameter of φ50 or less. These filters are often used as mesh injector filters, but they have a wide variety of other applications as well.

Stainless steel micro basket mesh filters are press-fitted into piping and widely used in refrigerant equipment such as air conditioners and refrigerators.

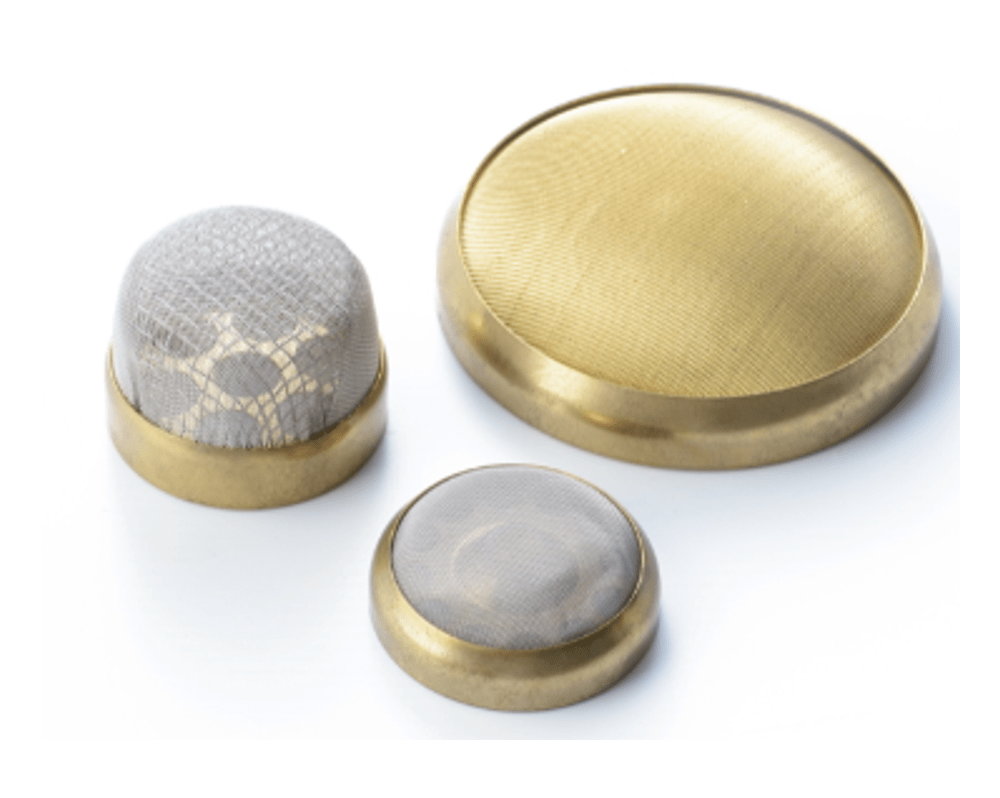

φ4.75 Micro Basket Filters

These are wire mesh filters whose rings have an outer diameter of φ4.75. They are the smallest type of micro basket filter produced by our company. We originally made them as prototypes at the request of an automobile parts manufacturer.

Stainless Steel Micro Basket Filters

These mesh filters are made of stainless steel. They are reinforced by a coarse wire mesh. They are used for high temperature environments such as in gas burners.

Brass Mesh Filters

Brass mesh filters created from a brass mesh screen. They are filters made of a brass ring and brass mesh caulked together. They are commonly used in air conditioning parts. (Dryer Filters, Compressor Filters)

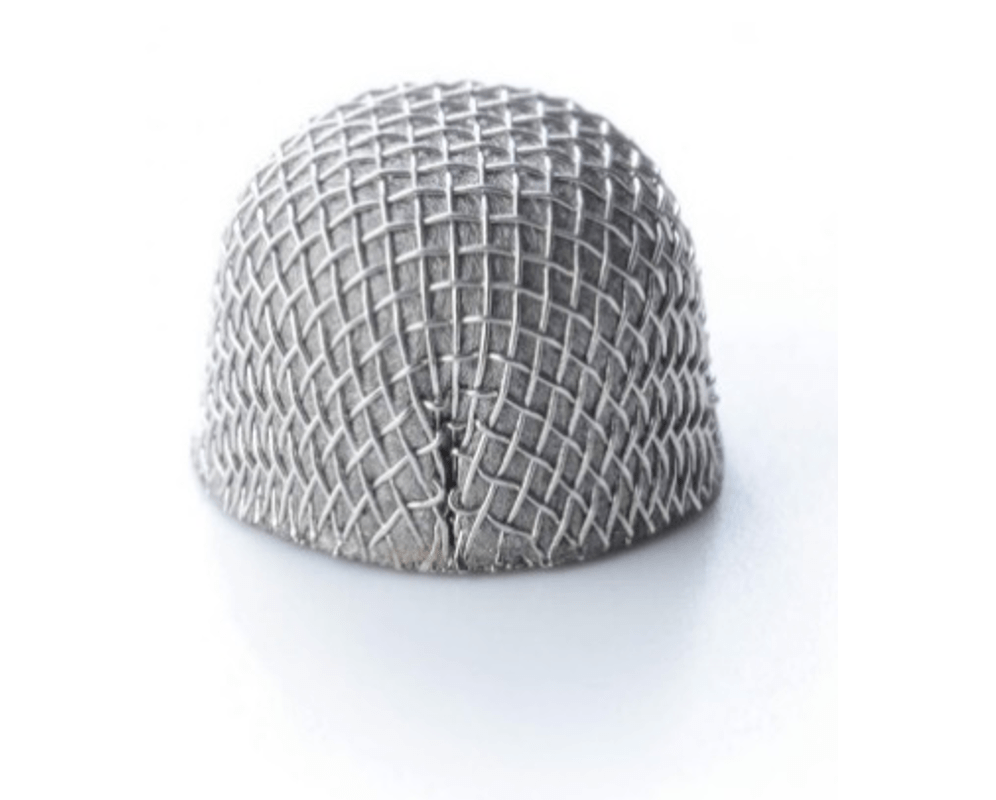

Baffle Plates

We have experience in manufacturing baffle plates / accumulator filters to Φ80. We can manufacture according to your requests for size, number of holes, shape of holes, material, etc.

Baffle plates are used in accumulators. Hence, they are also known as accumulator filters.

Separates refrigerant mixed with gas and liquid in the process of refrigerant cycle. In the refrigerant cycle, refrigerant may be a mixture of gas and liquid in need of separation. Accumulator Filters collect liquid particles, allowing only for the gas to pass through.

Non-woven Caulked Filters

These filters use non-woven metal fabric. These are capable of high and uniform filtration.

Brass Flange Filters

These are the standard flange type filters. They are used in air conditioning related parts.

Aluminum Flange Filters

These are flange type filters with an aluminum ring. They are used in car parts.

Welded Flange Filters

These are welded flange type filters with SuperDyma rings. They are used in large compressors.

Welded Type Wire Mesh Filters

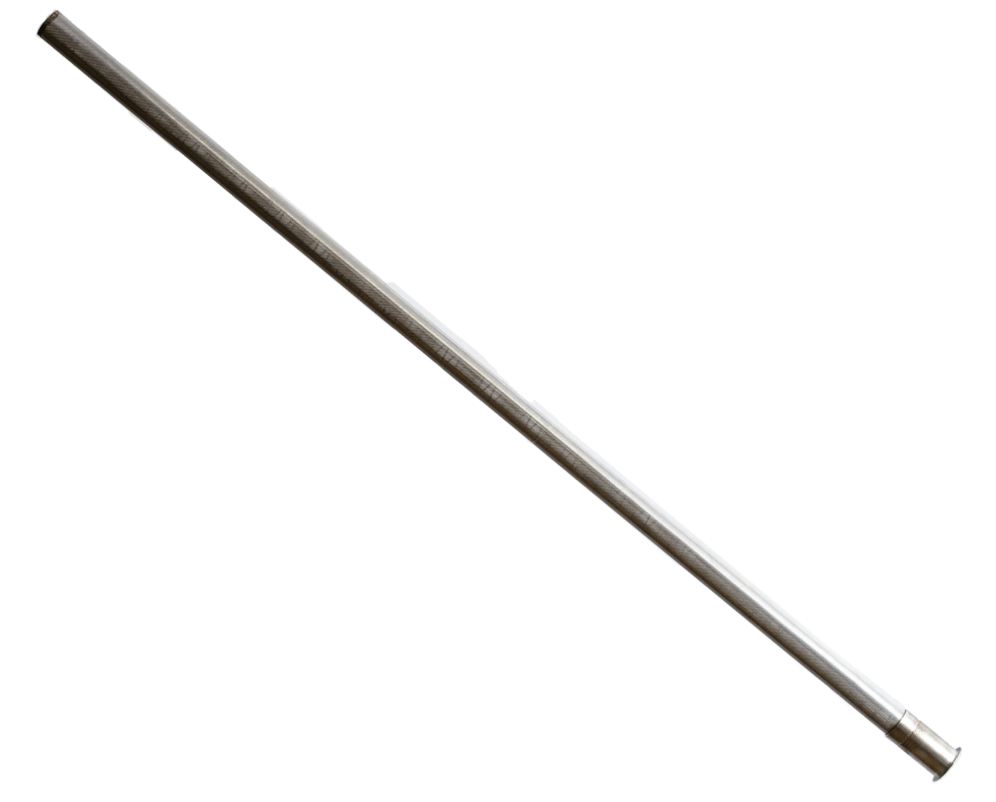

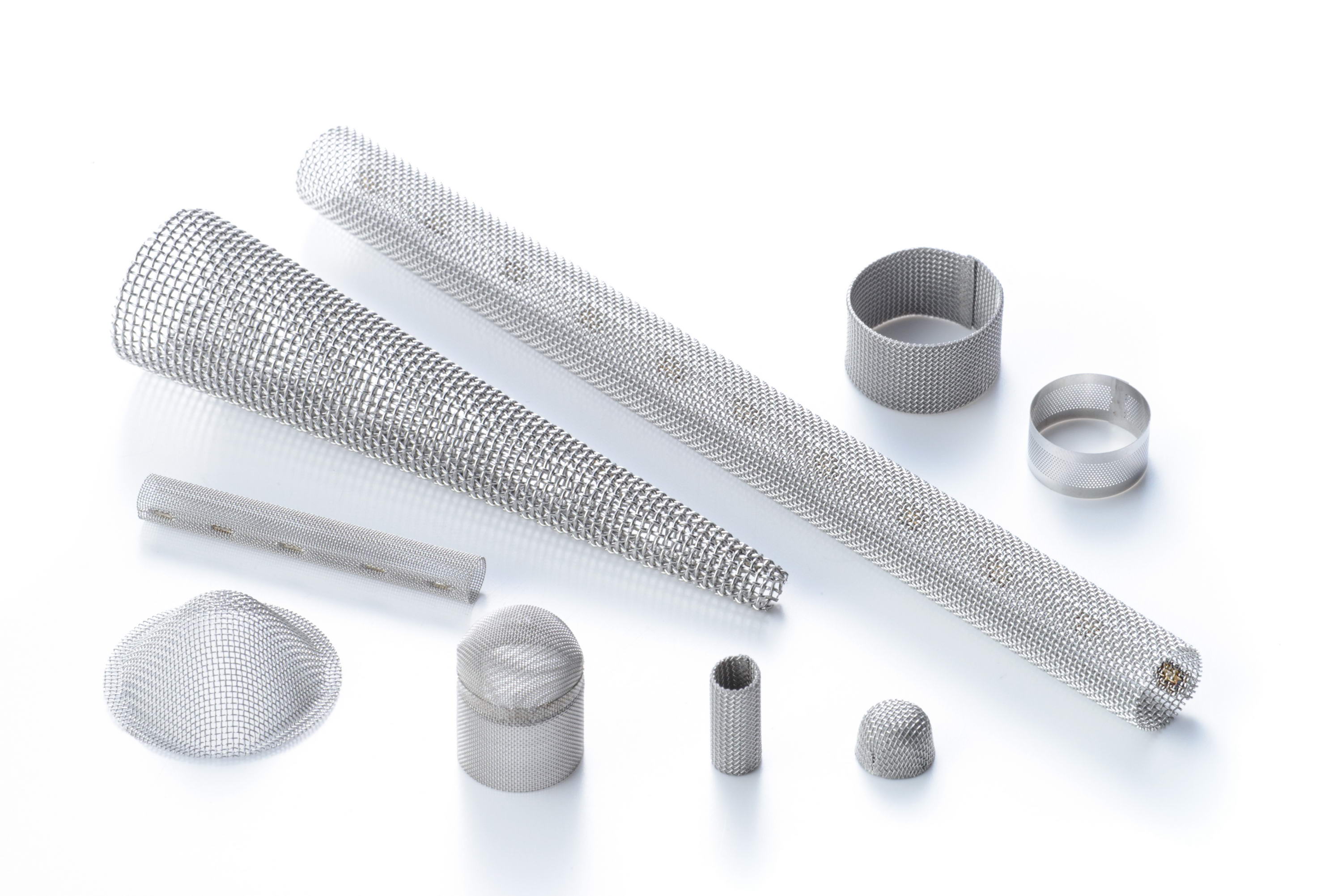

Welded Long Filters

It is difficult to blank and draw a filter with a large filtration area, and so the wire mesh is welded. We do this through spot or seam welding. It is press fitted into piping and widely used in refrigerant equipment such as air conditioners and refrigerators, and injectors for automobiles.

Spring-mounted Filters

By affixing a spring to the inside of the filter, the filter has high pressure resistance. It also prevents clogging by filtering from the opposite direction. It is press-fitted into piping and used for refrigerant equipment such as air conditioners and refrigerators.

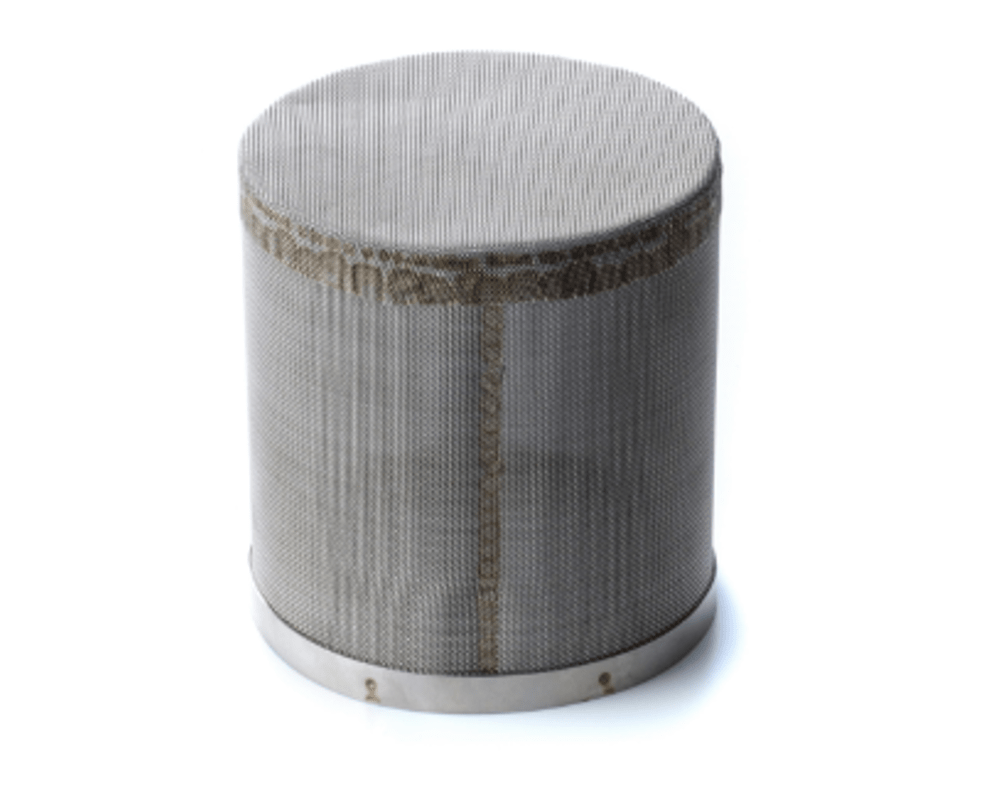

Multilayer Sintered Filters

These are high filtration accuracy welded sintered wire mesh filters. They are installed in both outdoor and indoor air conditioners in order to filter foreign substances.

Cleaning Baskets

After welding the mesh, a stainless steel plate is welded to the perimeter of the basket. We have produced them in a range of Φ70 to φ170. They are baskets used to collect scraps of trash during a given process.

Mesh Molded Type Filters

Blanked and Drawn Mesh

These are filters that have undergone the blank and draw process. They can be cut into various shapes, sizes, and mesh. These filters are car engine filters, solenoid valve filters, and water intake filters.

Blanked and Drawn Non-Woven Fabric

We use non-woven fabrics with high filtration accuracy and sintered woven mesh as a reinforcing material. This is a rare product developed with our company’s technology.

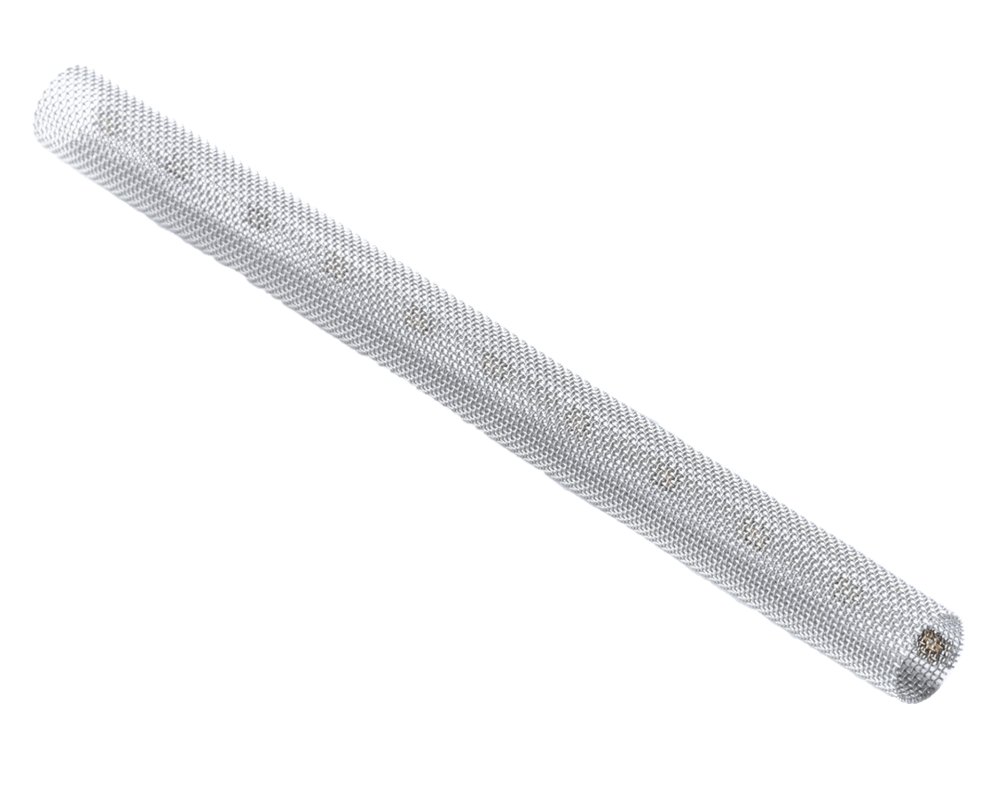

Cylindrical Mesh Filters

Mesh is rolled and then welded. They can be manufactured in a variety of mesh, sizes, and types. They are used in automobile parts. They are also used as mesh in resin molding.

Compressed Mesh Disc Filters / Coin Filters

By compressing the edges, the mesh disc filter is stronger than products without wire mesh. Reduces tooling costs, and negates the need for a ring.

Compressed mesh disc filters are used for water faucets, and gas equipment.

Cylindrical Non-Woven Fabric Filters

A non-woven fabric with a filtration accuracy of 25 µm is rolled and welded. If requested, a non-woven fabric with a filtration accuracy of 2 µm can be used. It is used in parts pertaining to Biofuel

Other Types of Specialized Filters

Y Strainer Filters

Perforated metal is used as reinforcement. Upper and lower caps are soldered.

Used for Y strainer.

Perforated Strainers and Filters

Perforated metal is rounded and welded. Made to your requested size, used for Y strainer.

8-Mesh Filter

Outer diameter Φ75, 8 mesh is used.

Used as air conditioner related parts.

Rolling Oil Filters

Two types of wire mesh are used and joined straight by spot welding. Stainless steel coils are used as reinforcement inside.

Rolling oil filter about 1m long. Used in old type rolling mills.

Resin Molded Filters

Resin / plastic Mold filters utilize metal mesh. Unlike nylon mesh, metal mesh can be used even in high temperature environments.

Etched Filters

These filters use etched materials. Unlike woven mesh it is make from a single plate and is characterized by no misalignment, fraying, or burrs.

Signature Product Examples

Wire mesh filters for air conditioners and compressors

| Type | Short mesh type, welded type |

|---|---|

| Application | Mesh Filters for Compressors |

| Size | 6.4~32.0(L)×4.0~30.0(H)mm (Customizable) |

| Product Detail | Blank type, weld type, various shapes。 |

| Mesh | Customizable. Two pieces of netting can be used as reinforcement. |

| Material | Wire mesh: brass, stainless steel, metal non-woven fabric, etc. Ring: brass material, stainless steel, etc. |

Accumulator filters

| Type | Drawn type mesh |

|---|---|

| Application | Gas-liquid separation filters in compressors, etc. |

| Size | Customizable |

| Product Detail | In the refrigerant cycle, refrigerant may be a mixture of gas and liquid in need of separation. Accumulator Filters collect mist within the gas, allowing only for the gas to pass through. |

| Mesh | Customizable. Two pieces of mesh can be used as reinforcement. |

| Material | Wire mesh: brass, stainless steel, metal non-woven fabric, etc. Ring: brass material, stainless steel, etc. |

Wire Mesh Filters for injectors

| Type | Short drawn type mesh |

|---|---|

| Application | Filter used within injectors |

| Size | Outer diameter φ4.75~ Please refer to the caulking/short type diagram in the existing strainer size list for a view of sizes. |

| Product Detail | Nylon filters used within injectors may be deteriorated and damaged by ethanol in the fuel. However metallic filters do not have this problem and will not be affected by ethanol damage. |

| Mesh | Plain weave wire mesh, twill weave wire mesh, laminated sintered wire mesh, laminated nonwoven fabric, etc. We can make proposals according to the filtration particle size. |

| Material | Stainless steel SUS304, SUS316, brass, etc. |

Water supply rectifiers, Solenoid valve filters, Pneumatic machines, etc.

| Type | Other types |

|---|---|

| Application | Water filter mesh, solenoid valve filters, pneumatic equipment, etc. |

| Size | 3.2 ㎜ ~ |

| Product Detail | We can produce products with compressed edges or drawn edges, etc., according to the customer’s instructions. |

| Mesh | Customizable. |

| Material | Sintered wire mesh prevents misalignment. 1 to a maximum of 5 pieces of wire mesh can be sintered. |

Other automotive filters

| Type | Spot welding type, caulked type |

|---|---|

| Application | Automobile engines, injectors, etc. |

| Size | φ 4.74 mm 〜 80 mm (Customizable) |

| Product Detail | Mesh and metal fittings will be selected and manufactured according to the customer’s intended use. |

| Mesh | Customizable. Two pieces of mesh can be used as reinforcement. |

| Material | SUS, brass, aluminum, SuperDyma, etc. |

Filters for fuel cell vehicles

| Type | Welding type, punching type |

|---|---|

| Application | Fuel cell vehicles, etc. |

| Size | Customizable |

| Product Detail | These are filters with a lot of possible customization. They are produced with extremely advanced technology. Welding can be finished by bright annealing (a method of heat treatment). We can provide one to ten million pieces per lot. We can provide one piece to tens of millions of pieces/lot in integrated production. |

| Material | We can accommodate a variety of materials and shapes to meet customers’ requirements. |