Eliminating Wire Mesh “Fraying” Through a Special Cutting Method

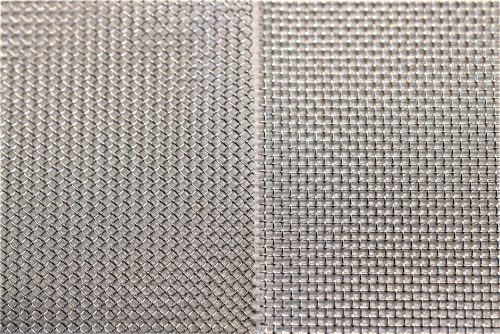

Left: Wire mesh cut diagonally

Right: Wire mesh cut along the mesh

| User | Overseas manufacturer of gas safety devices |

|---|---|

| Issues and Requests | We received an inquiry for a new product, and manufactured a metal mesh filter with an outer diameter of φ6. This type of filter is one of the three standard types of filters we manufacture, so we did not expect to encounter any issues during production. However, when we manufactured this mesh filter, we found that the wire mesh was slightly frayed at the edges. Although this fraying did not immediately pose an issue, our customer was concerned that the wire mesh scraps might be mixed into the next process, and asked if there was any way to eliminate this fraying. |

| Solution | For customers who are worried about fraying, we normally propose sintered wire mesh. Sintered wire mesh is a type of wire mesh that prevents fraying and misalignment or fraying by welding (sintering) wire rods together. However, the 300-mesh wire mesh used in this project was very thin (φ0.04), so the wire mesh could tear during the sintering process. There is a method achieving this without welding, but this would require the creation of a new die. This was not an ideal solution for our customer, who wanted to avoid taking on extra expenses. Our engineering department then suggested changing the cutting direction of the wire mesh. The wire mesh had previously been cut parallel to the mesh, but we decided to cut it at an angle to the mesh. We manufactured the product with the diagonal cut, and as expected by our engineering department, the occurrence of fraying was reduced. We succeeded in solving the user’s problem without incurring additional costs with this special diagonal cut. |