Removing Weld Burns by Bright Annealing

| User | Automotive parts manufacturer |

|---|---|

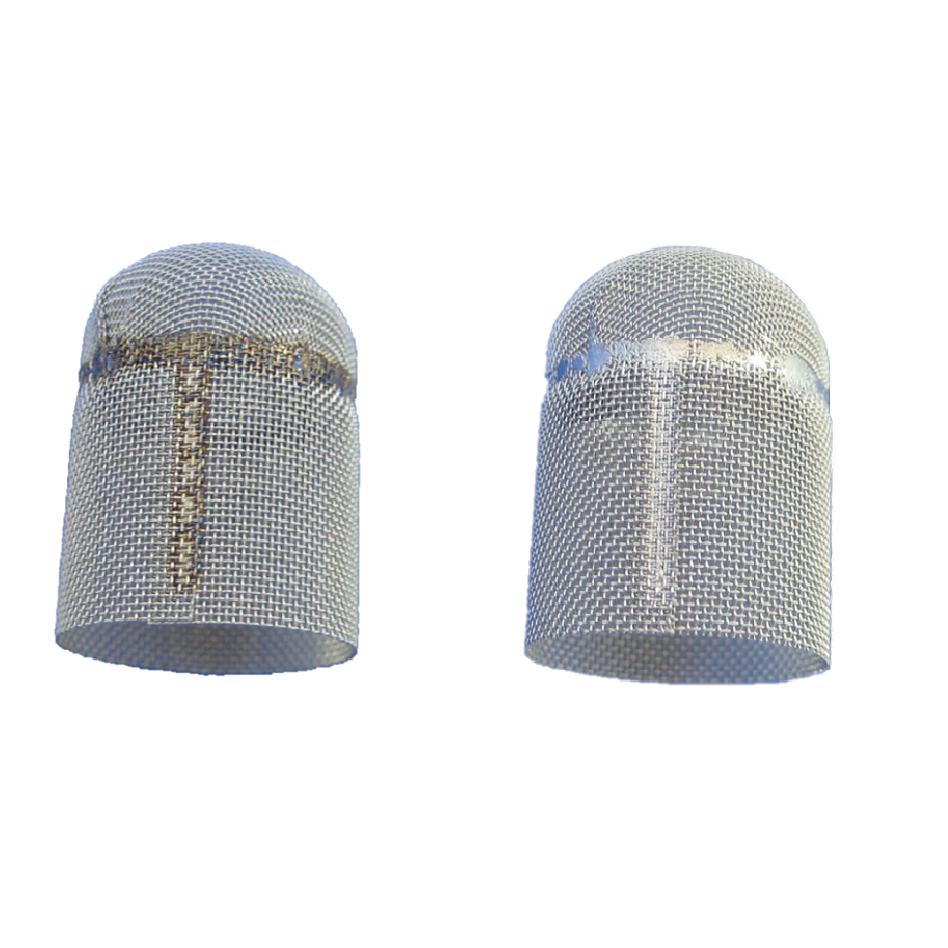

| Issues and Requests | We received a request from a customer to improve the quality of a current product. The filter consisted of wire mesh, but when welded, the intense heat caused weld burns. Weld burns can result in black discoloration and oxidation of the mesh. This is not something you want for your product. This kind of discoloration is not only unsightly, but if left unchecked, corrosion could spread from the burnt areas and erode the surrounding area. Stainless steel is inherently rust-resistant, but when welded, heating causes a diffusion phenomenon in the chromium, which impacts the corrosion-resistant performance of the stainless steel. |

| Solution | To eliminate concerns about corrosion, we proposed the removal of weld burns through bright annealing treatment. Bright annealing is a treatment method that reduces oxides by heating and cooling in a reducing atmosphere of hydrogen. Products that have undergone this treatment will have a beautiful finish and will not corrode from burnt areas, even after extensive use. Oxidation of the weld area was successfully removed, maintaining the integrity and performance of the filter. |