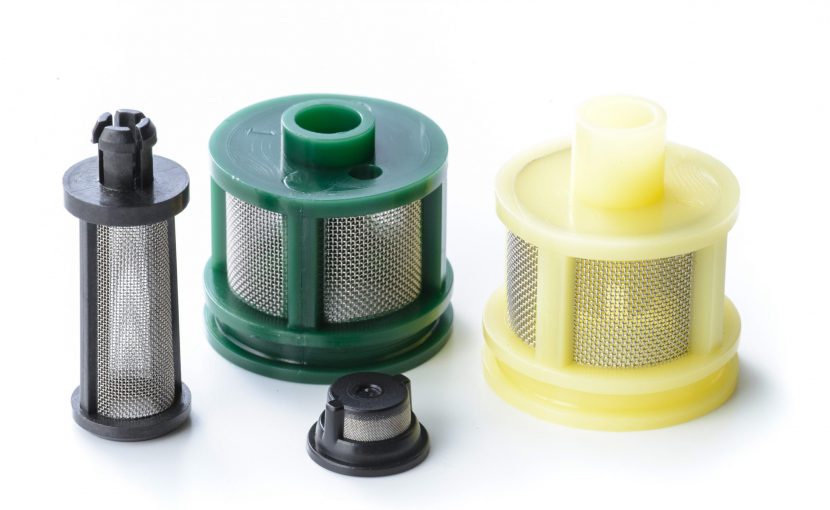

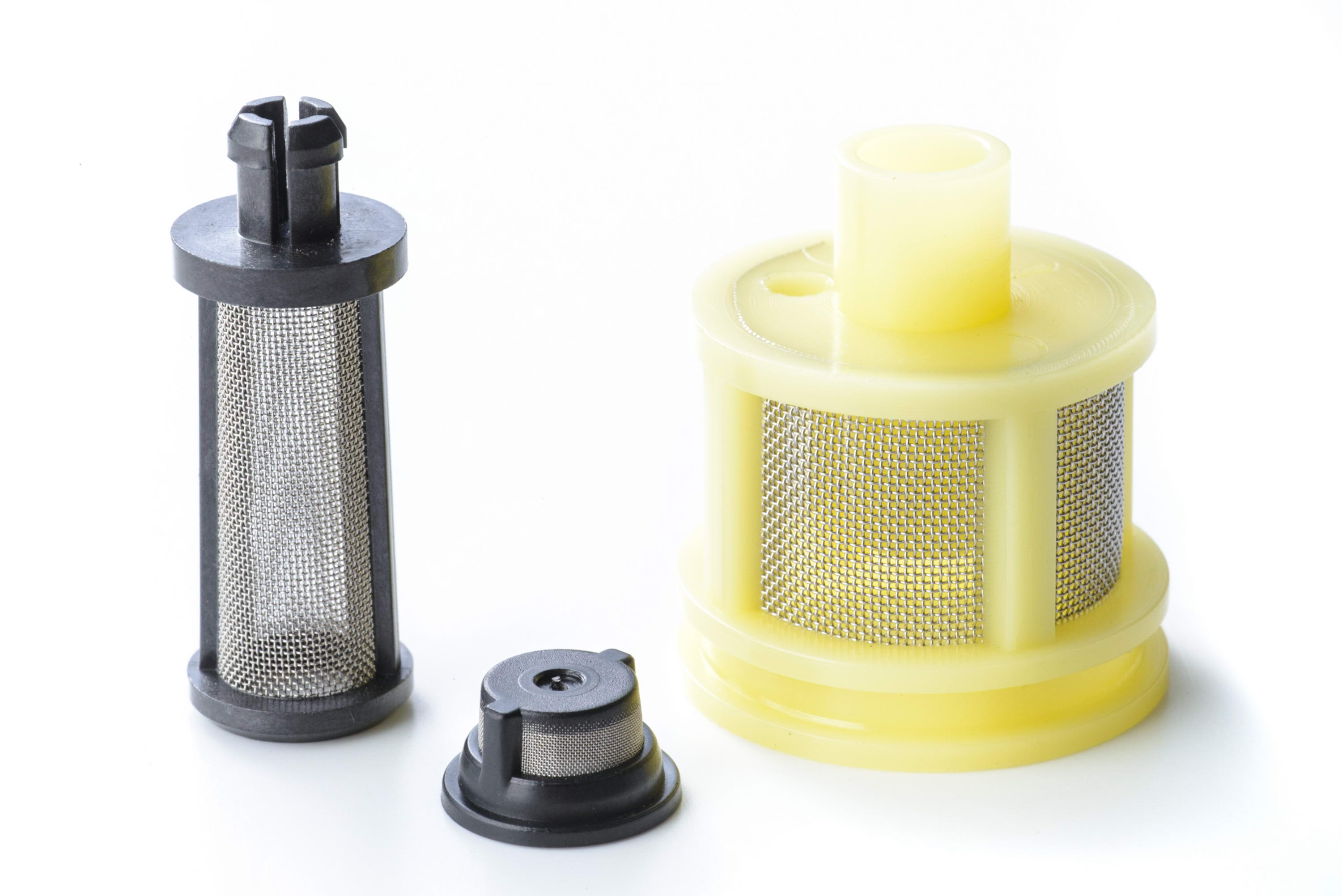

What is a Resin Molded Filter / Insert Molded Filter?

Resin molded filters are a cost effective and precise filtration solution. They can be made in just about any size or shape, making them very useful for a wide variety of custom applications– water heater filters, medical device filters, engine oil filters for automobiles and many, many more.

Resin molded mesh filters / insert molded filters, as the name implies, are made via insert molding. This is the process injecting liquid resin into a mold. In the case of resin molded filters, the liquid resin bonds with filter mesh inside the mold.

The Key Benefits of Resin Molded Filters / Insert Molded Filters

Consistent

Consistency is key. There is little chance of deviation in the filters produced, regardless of lot size.

Cost Effective

Resin molded filters and plastic insert molded filters have a low unit price, and can be produced in very high lot numbers.

Customizable

Resin and plastic insert molded filters can be made in any size or shape to meet your business needs.

In Conclusion

Resin molded filters and plastic insert molded filters are an excellent choice for a wide variety of applications. If you need a high quantity of precise and reliable filters at a low cost, you should consider taking advantage of plastic insert molding.

| Type | Resin Molded Filter |

|---|---|

| Usage | Water heaters, filters for medical devices, Engine oil filter for automobiles etc. |

| Size | Customizable |

| Product details | Made from resin insert molding, resin molded filters are highly customizable filters that can be manufactured into countless shapes and sizes. These filters can be used in high temperature environments. |

| Material | Molded Resin / Plastic and stainless steel wire mesh. |

FAQ about Resin Molded Filters / Insert Molded Filters?

Can resin molded filter specifications be customized?

Yes, the filter’s materials, dimensions, shape, construction method, mesh size, and applications are all fully customizable.

Do you need drawings for production?

No, Vantech can consult with you to make a drawing based off a description or image of the filter you may have. No drawing is necessary to get started.

What are the common weaving types for resin molded filters?

Plain weave mesh is the most common, but other options such as twill weave mesh are also used. The benefit of using plain weave mesh is that it is the most popular and affordable

What situations can be anticipated in which resin molded filters should be selected?

Resin molding is better for mounting in the case of sandwiching. This is because it can be made without gaps in the shape of the mounting partner.