What is Rolling Oil Filters for Cold Rolling Mills?

Rolling oil filters are a type of filter used in cold rolling mills, which are industrial machines used to reduce the thickness of metal strips or sheets by passing them through a series of rollers.

Cold rolling mills use a variety of fluids, including rolling oil, to help reduce friction and heat generated during the rolling process, which can cause damage to the rollers and the metal being rolled.

Rolling oil filters are designed to remove contaminants from the rolling oil, such as metal particles, dirt, and debris, which can reduce the effectiveness of the oil and cause damage to the rollers and the metal being rolled.

The filters are typically located in the oil circulation system, and can be made from a variety of materials depending on the specific requirements of the rolling mill. Regular maintenance and replacement of rolling oil filters can help ensure the smooth operation of the cold rolling mill and extend the life of the equipment.

The Key Benefits of Rolling Oil Filters for Cold Rolling Mills

Experienced

It is difficult to weld long shaped filters, but we can do it.

Straight Shaped

It is difficult to create a straight shape, but we can do it with our many years of experience and know-how.

Available for Consultation

Because of our know-how, we can give you advice on mesh selection and other aspects of filter making.

| Type | Spot welding type (*No sample available) |

|---|---|

| Application | Rolling Oil Filters for Rolling Mills |

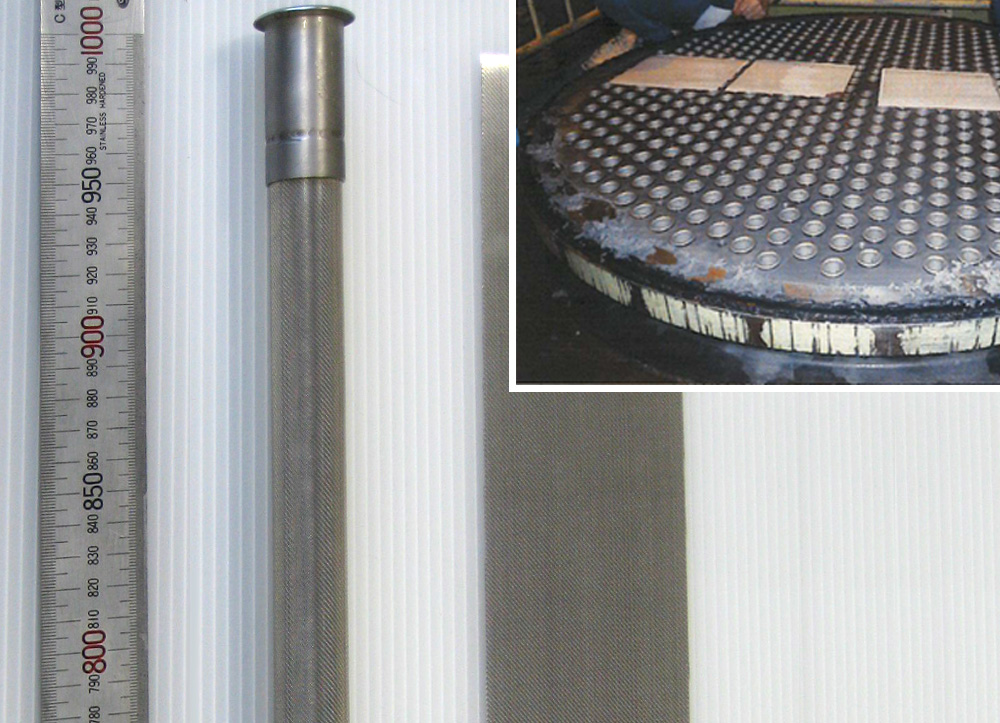

| Size | 25mm(φ) dia. x 972(L) mm |

| Product Detail | Twilled weave 55 mesh is rounded and spot welded straight together. A stainless steel coil is used inside as reinforcement. A stainless steel mouthpiece is joined to one side and the mesh to the other. |

| Material | SUS304 |

FAQ about Rolling Oil Filters for Cold Rolling Mills?

Can the filter specifications be customized?

Yes, the filter’s materials, dimensions, shape, construction method, mesh size, and applications are all fully customizable.

Do you need drawings for production?

No, Vantech can consult with you to make a drawing based off a description or image of the filter you may have. No drawing is necessary to get started.

What are the common weaving types for the filter?

Three-layer sintered mysid is often used in the manufacture of this type of filter.

The advantage of three-layer sintering is that it offers a good balance of filtration accuracy and strength.

Other multi-layer sintered mysid is also used.

What situations can be anticipated in which this filter should be selected?

If you are considering long cylinders, this type is a good choice.