What is Bright Annealed Filters?

Bright annealed filters are specialized filters used in the manufacturing of stainless steel and other metal products.

Bright annealing is a process in which a metal is heated in a controlled atmosphere to a specific temperature and then cooled rapidly. This process is used to improve the mechanical and chemical properties of the metal, including its strength, ductility, and resistance to corrosion.

Bright annealed filters are used to remove impurities from the controlled atmosphere used in the annealing process. These filters are typically made from materials that are resistant to high temperatures and chemical corrosion, such as stainless steel or ceramic.

They are designed to capture and remove impurities such as dust, dirt, and other contaminants that could interfere with the annealing process or contaminate the metal being annealed. Regular maintenance and replacement of bright annealed filters is important to ensure the quality and consistency of the annealed metal products.

The Key Benefits of Bright Annealed Filters

Rust Resistant

After bright annealing treatment, it will not rust and can be used for a long period of time.

Good Appearance

It can be used even when filter rust is unacceptable.

It is often used for products that need to look good.

Quick & Economical

We have our own annealing machines, so we can respond quickly and inexpensively.

Bright Annealing Prevents Rust and Treats Discoloration

As the name suggests, stainless steel is a rustproof (strictly speaking, rust-resistant) metal. It doesn’t stain. This is because the chromium in stainless steel combines with oxygen in the air to form a passive film on the surface. Well, this is the case normally. But the intense heat from welding actually destroys this chromium film. It is very clearly seen in the unappealing discoloration from the weld area. Corrosion and rust can progress from the discolored area, and causing this so called “stainless” steel to rust.

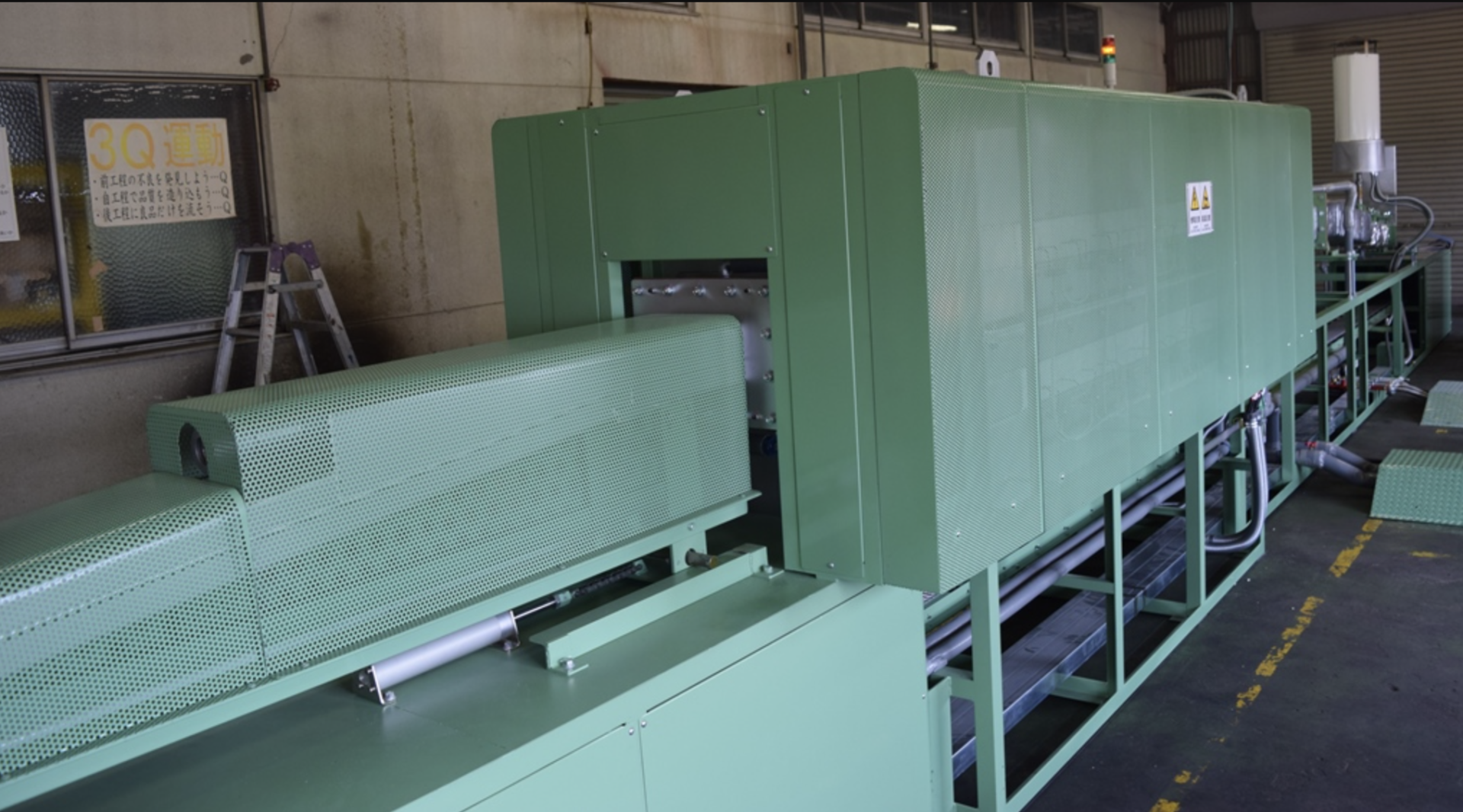

Bright Annealing Equipment

This machine, which our company purchased several years ago, can be used in such cases. This equipment performs bright annealing, reduction treatment, and diffusion bonding of stainless steel parts (strainers and filters).

It consists of a continuous heating furnace and control panel, and the treated material is conveyed by a heat-resistant steel mesh belt for non-oxidation heat treatment. This is opposed to oxidizing treatments such as conventional welding.

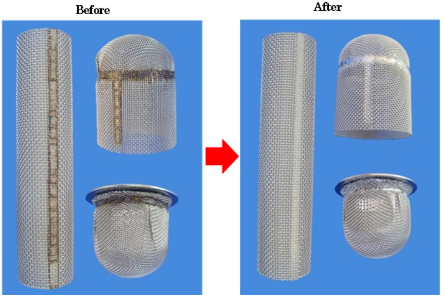

Before and After Bright Annealing

When wire mesh is welded through conventional means, the welded area becomes discolored as evident on the left image. Bright annealing reduces oxides by heating and cooling in a reducing atmosphere of hydrogen, and the discolored areas can be removed.

Products that have undergone bright annealing treatment are free from rust and discoloration, and last for a long time. Consider bright annealing mesh for your project, if you are looking to build a filter with extended longevity.

Where non-oxidation heat treatment is performed

Interested in Bright Annealing?

Contact Us!

FAQ about Bright Annealed Filters?

Can bright annealed filters specifications be customized?

Yes, the filter’s materials, dimensions, shape, construction method, mesh size, and applications are all fully customizable.

Do you need drawings for production?

No, Vantech can consult with you to make a drawing based off a description or image of the filter you may have. No drawing is necessary to get started.

What are the common weaving types for this filter?

Stainless steel is the material of choice for weaving because it is rust-free. Annealing is also effective in increasing the corrosion resistance of welds.

What situations can be anticipated in which bright annealed filters should be selected?

Bright annealing is the best choice when you want to improve appearance and corrosion resistance.