What is Fuel Cell Filters?

Fuel cell filters are specialized filters designed to remove impurities and contaminants from the fuel that is supplied to fuel cells. Fuel cells are electrochemical devices that generate electricity by converting the chemical energy of a fuel, typically hydrogen, into electricity and water through a chemical reaction.

Fuel cell filters are critical components in fuel cell systems as they help to prevent contamination and degradation of the fuel cell catalyst and other components. These filters can remove a wide range of contaminants, such as particulates, water, oil, and other impurities that can cause damage or reduce the efficiency of the fuel cell.

Fuel cell filters typically use a combination of physical and chemical filtration methods to remove contaminants from the fuel. The filters may be made of various materials, such as metal, ceramic, or polymer, depending on the specific application and fuel cell type.

In addition to fuel cell filters, other components of fuel cell systems may also require filtration, such as air filters to remove contaminants from the air that is supplied to the fuel cell, and water filters to remove impurities from the water that is used to generate hydrogen.

Overall, fuel cell filters are essential for ensuring the proper operation and longevity of fuel cell systems. They help to ensure that the fuel cell operates efficiently and reliably, and they are critical for many applications that rely on fuel cell technology, such as electric vehicles and portable power systems.

The Key Benefits of Fuel Cell Filters

Freeform

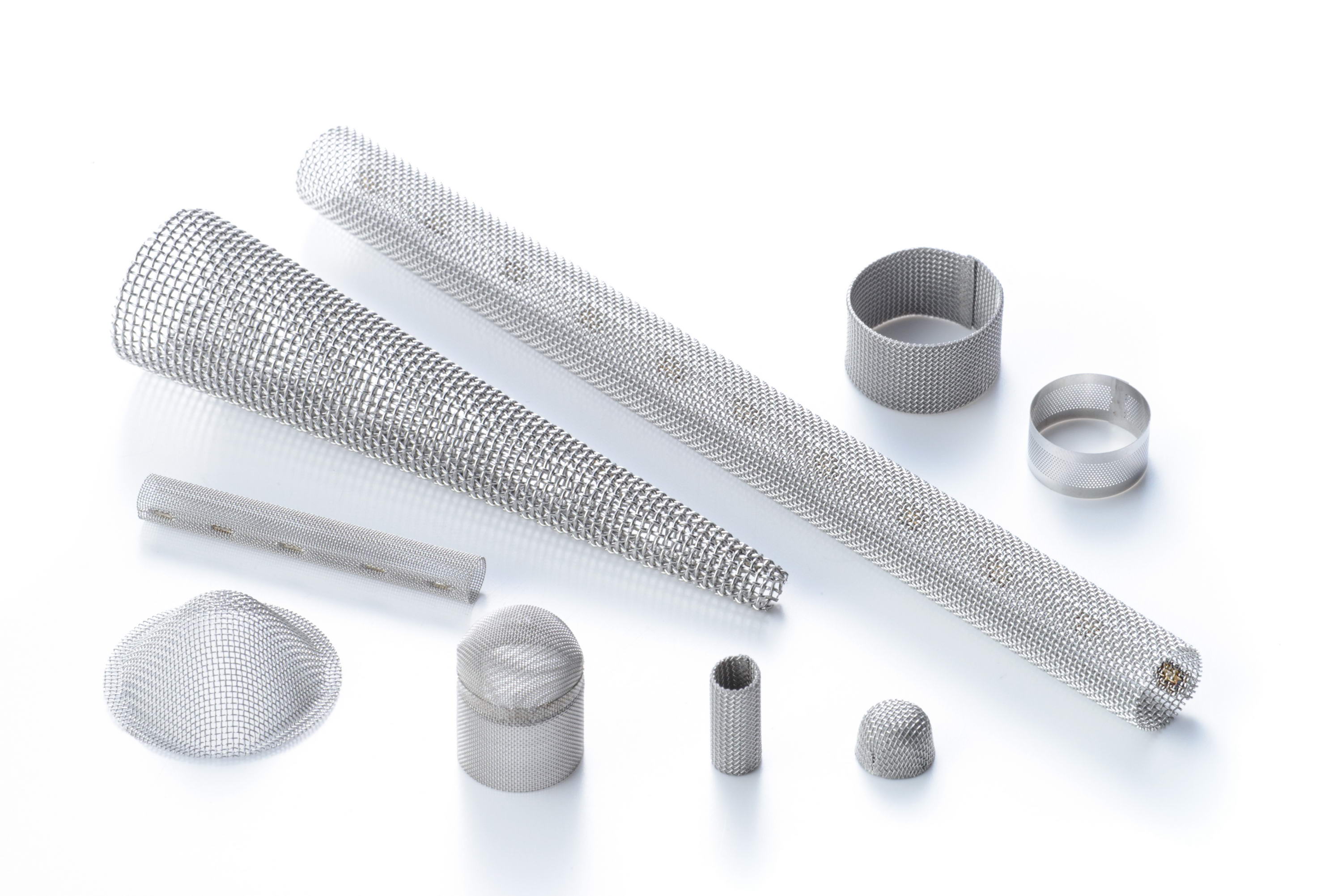

This filter can be squeezed into a variety of shapes.

Free-form shapes can also be created by welding.

Processable

Special sintered screen mesh can also be used in production.

Wire mesh and perforated metal can also be used.

Fast & Economical

The filter can be made by press punching.

If it is a die-drawing type, the material can be automatically pulled out from the roll to make it, so it can be done quickly and at a reasonable cost.

Precision filter using wire mesh with filtration accuracy of 2μm~

| Type | Welding type, Punching type |

|---|---|

| Application | Fuel Cell Vehicles |

| Size | Customizable |

| Product Detail | We process wire mesh in the desired shape. We can produce wire mesh with very high technology and finish weld burns by bright annealing (heat treatment method). We can handle everything from a single prototype to mass production through integrated production. |

| Material | We can accommodate a variety of materials and shapes to meet customers’ requirements. |

FAQ about Fuel Cell Filters?

Can fuel cell filters specifications be customized?

Yes, the filter’s materials, dimensions, shape, construction method, mesh size, and applications are all fully customizable.

Do you need drawings for production?

No, Vantech can consult with you to make a drawing based off a description or image of the filter you may have. No drawing is necessary to get started.

What are the common weaving types for cylindrical air filter elements?

Plain weave mesh is commonly used for this filter.

The advantage of using plain weave mesh is that it is the most popular for removing foreign matter and can be made inexpensively.

Tatami weave mesh can also be used.

What situations can be anticipated in which cylindrical air filter elements should be selected?

We can accommodate any shape as shown in the photo above, regardless of the fuel cell. We can also provide mesh screen only.