What is Metal Filters for Compressors?

Mesh filters and strainers are often used in compressors. Compressors add pressure to refrigerant gas in an air conditioning unit which cycles it through the ac system. These mesh filters protect the air conditioning unit during the refrigerant cycle. Mesh filters are installed in other parts of the air conditioning unit as well.

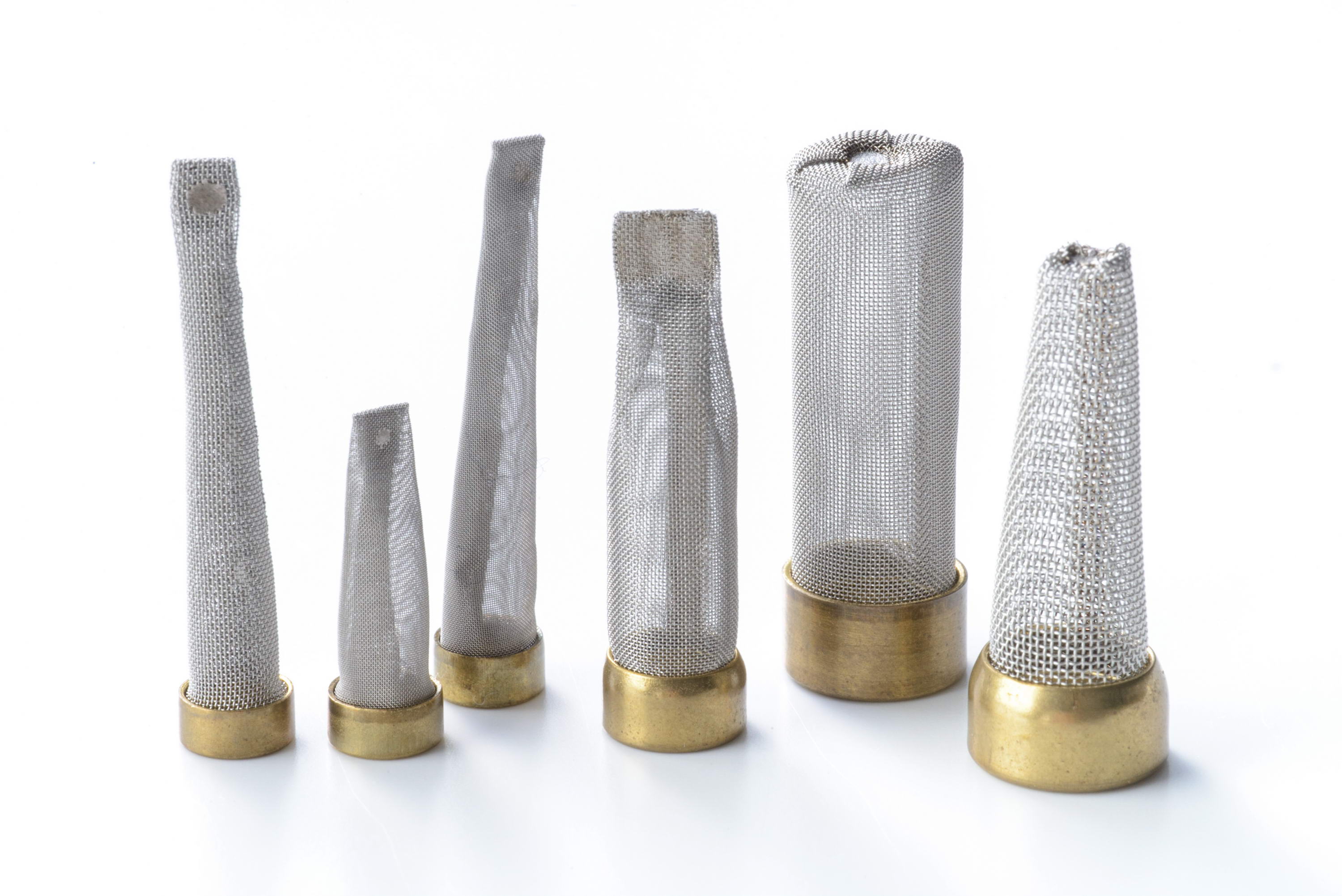

Metal filters for compressors can be made of various materials, including stainless steel, aluminum, and brass. They come in a range of shapes and sizes to fit different compressor models and applications.

Metal filters for compressors are critical for ensuring the proper operation and longevity of the compressor. Without a filter, contaminants can cause wear and tear on the compressor’s components, reduce efficiency, and lead to breakdowns. These filters are typically installed on the inlet side of the compressor, and they can be easily replaced or cleaned as needed to maintain optimal performance.

In addition to removing contaminants, metal filters for compressors can also help to regulate the flow of air, prevent pressure drops, and protect downstream equipment from damage. Overall, they are an essential component of any compressed air system.

The Key Benefits of Metal Filters for Compressors

Selectable Molds

We have many molds, but even if you don’t have them, we can make them.

High-volume Production

For mass production, automatic assembly can be used for economical production.

Fast and Economical

Standard type allows for “fast” and “economical” production.

| Type | Small mesh type |

|---|---|

| Usage | For interior compressor filters |

| Size | 6.4~32.0(L)×4.0~30.0(H)mm Customizable Smallest size: outer dia. 4.75mm (prototype) Go to standard size chart |

| Product details | We manufacture various shapes, such as caulking type and welding type. |

| Mesh | Customizable. Two meshes can be used as reinforcement material. |

| Material | Wire mesh: Brass, Stainless steel, Metallic non-woven fiber etc. Ring: brass material, stainless steel, aluminum, etc. |

FAQ about Metal Filters for Compressors?

Can the filter specifications be customized?

Yes, the filter’s materials, dimensions, shape, construction method, mesh size, and applications are all fully customizable.

Do you need drawings for production?

No, Vantech can consult with you to make a drawing based off a description or image of the filter you may have. No drawing is necessary to get started.

What are the common weaving types for metal filters for compressors?

The mesh patterns commonly used for these filters are plain weave mesh and twill weave mesh.

The advantage of using a plain weave mesh pattern in particular is that it is the most popular for removing foreign matter and can be made inexpensively.

However, sintered screen is also sometimes used.

What situations can be anticipated in which metal filters for compressors should be selected?

If a larger filtration area is required, double weave mesh can be used.

When both filtration accuracy and strength are required, double mesh can be used as one of the features of this filter.